OTT STANDARD 2 Diffusers – Versatile Connection Options For Round and Rectangular Headers

-

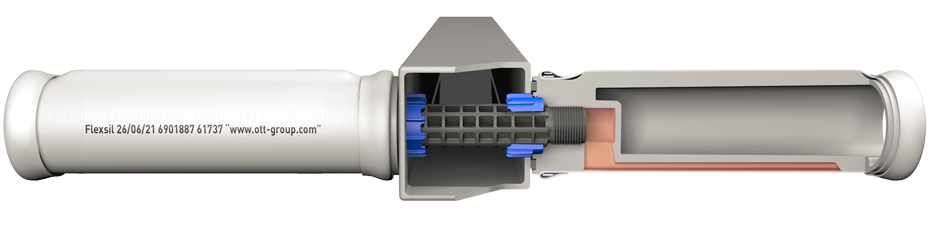

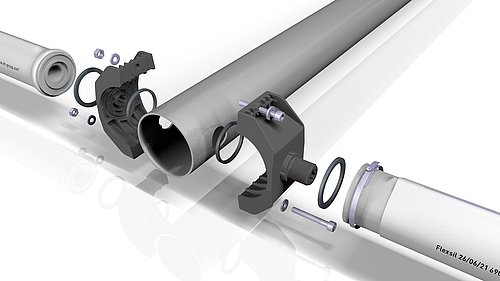

Mounting Rings

Stainless-steel clamp bands. Located at both ends of membrane, i.e. beneath each inverted membrane end.

-

Membrane

FLEXSIL® or FLEXNORM® tubular membranes are ideally suited for a wide range of wastewaters and applications. Their consistently high performance and reliability are ensured by highest quality standards and stringent quality assurance. Each diffuser carries a printed lot number for QA traceability.

-

Wrinkle-Free Membrane

OTT diffuser bodies are designed with a patented geometric shape which ensures a wrinkle-free membrane even when air infeed is discontinued, e.g. in intermittent operation. This unique feature is essential for maximum integrity and service life of the membranes.

-

Perforation

STANDARD 2 diffusers incorporate precisely engineered perforation which provides outstanding bubble distribution and uniform air release. This clearly sets us apart from competitors – as demonstrated by numerous trials conducted by independent test institutions. Custom perforation can be provided in accordance with your specific requirements. For more information – contact us!

-

PP Diffuser Body

The body of the STANDARD 2 diffuser is a monolithically injection-moulded tube made from eco-friendly, recyclable polypropylene (PP). The STANDARD 2 diffuser body’s expertly engineered shape and construction provide users big benefits.

-

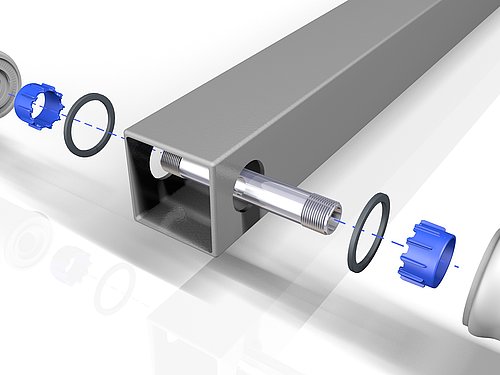

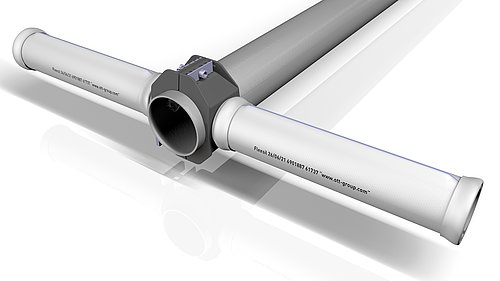

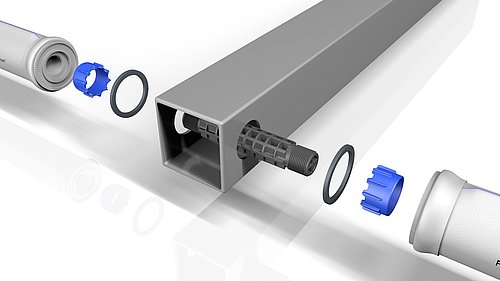

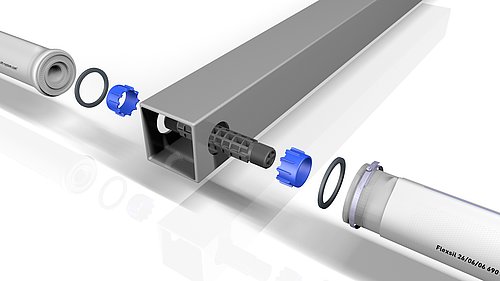

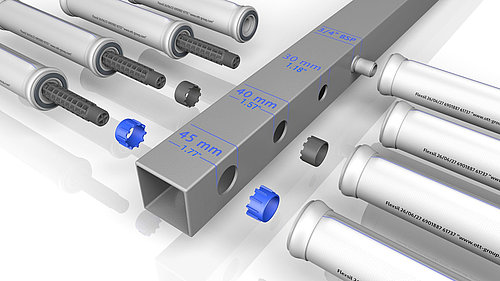

Connector

STANDARD2 diffusers are installed quickly and easily on rectangular headers with 30mm, 40mm or 45 mm (1.18", 1.57" or 1.77") diameter outlet openings. They are installed in pairs using double-threaded connectors available in engineering plastic PP-GF, VA-grade stainless steel or brass.

-

Threaded Receiver

The diffuser incorporates a ¾" inner-threaded insert made from high-strength engineering resin POM (polyoxymethylene) which is screwed down over the connector’s outer threading to mate the two completely together. STANDARD diffusers are available in 3 versions for rectangular headers: for 30, 40 or 45 mm diameter air-supply openings. Connection adapters are available to accommodate other diameters as well as round header lines.

-

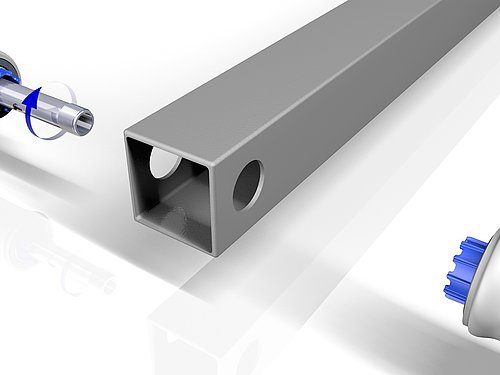

Continuous Air Channel

STANDARD 2 diffusers incorporate an end-to-end air channel at the bottom of the body which ensures uniform air distribution along the diffuser’s length.

-

Flooded Core

STANDARD 2 diffusers are open at the body‘s outer end, permitting partial flooding and therefore reducing buoyancy.

-

Lengths

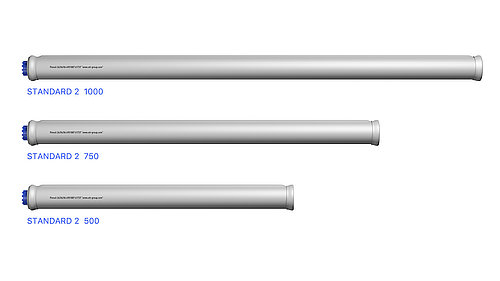

STANDARD 2 diffusers are available in effective lengths of 500, 750 and 1000 mm. The overall diffuser length of each version is 24 mm longer.

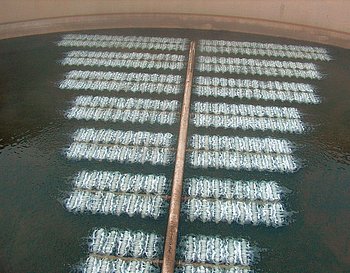

OTT STANDARD 2 is the ideal tube diffuser for retrofit installation in existing wastewater treatment facilities. Like all OTT tube diffusers, STANDARD 2 incorporates patented engineering features including an integrated air channel for uniform air flow distribution along the diffuser’s length and a membrane mounting ridge ensuring secure and wrinkle-free membrane positioning.

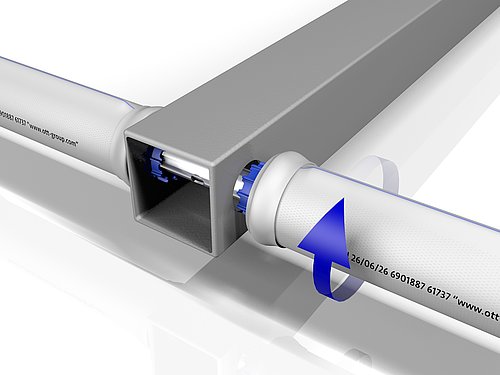

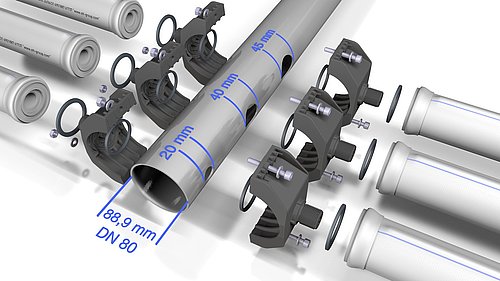

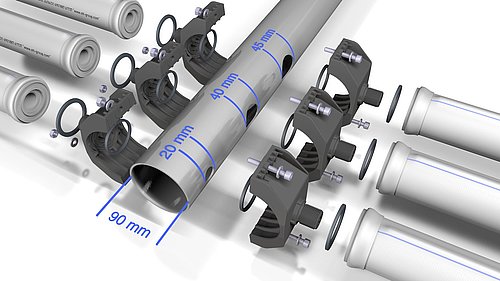

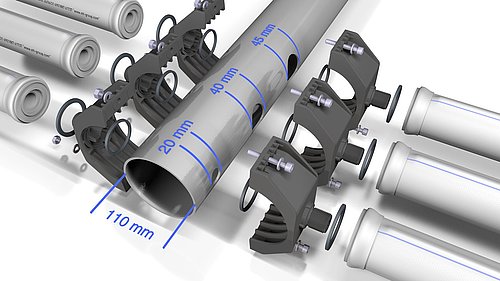

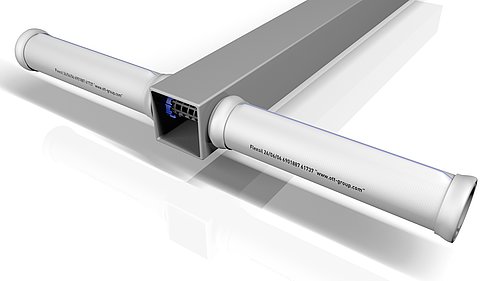

OTT STANDARD 2 diffusers are installed quickly and easily on rectangular headers with 30, 40 or 45 mm (1.57" or 1.77") diameter outlet openings. They are installed in pairs using double-threaded connectors available in engineering plastic PP-GF, alternatively in VA-grade stainless steel or brass.

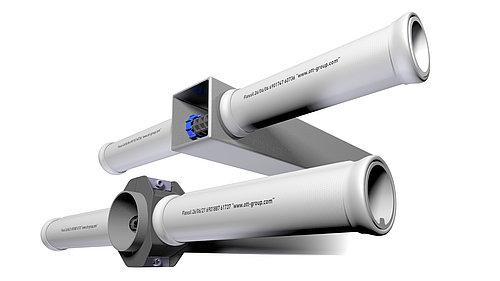

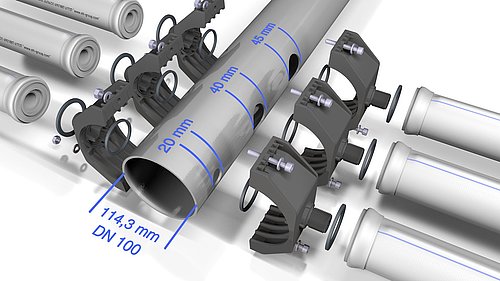

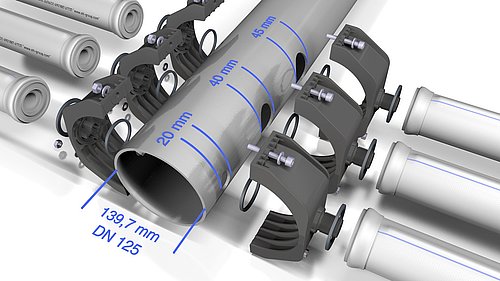

OTT STANDARD 2 diffusers can also be installed on round headers with 20 mm (0.79") diameter outlet openings. A saddle-contoured adapter ensures secure mounting. These rugged adapters provide reliable service at high operating temperatures along with outstanding resistance to formic acid.

OTT STANDARD 2 tube diffusers are available from stock in effective lengths of 500, 750 and 1000 mm (19.69", 29.53 and 39.37"). Custom lengths, e.g. for trailer-mounted treatment units or MBR modules, can be fabricated in exact accordance with your specifications.

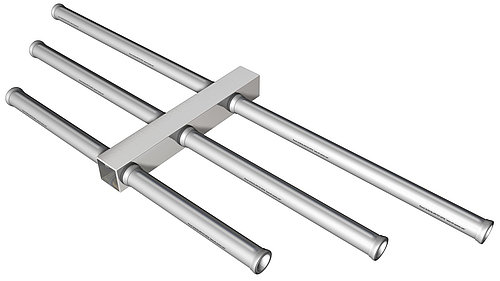

STANDARD 2 Installation

STANDARD 2 Comparison

STANDARD 2 on Round Header

STANDARD 2 on Rectangular Header

Carbon Footprint

Feel free to contact us so that we can work together to reduce the energy consumption and carbon footprint of your aeration system. We describe the measures that we implement in our sustainability report.

CO₂ emissions for diffuser production

| FLEXNORM® | FLEXSIL® | |

|---|---|---|

| STANDARD 2 500 | 1,67 kg CO₂ | 1,21 kg CO₂ |

| STANDARD 2 750 | 2,33 kg CO₂ | 1,63 kg CO₂ |

| STANDARD 2 1000 | 2,97 kg CO₂ | 2,11 kg CO₂ |

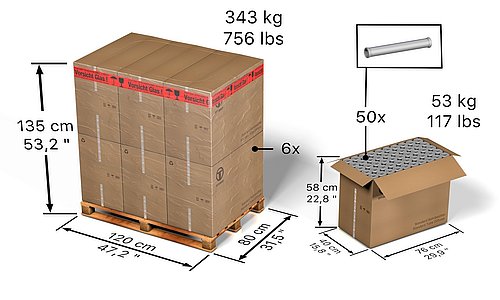

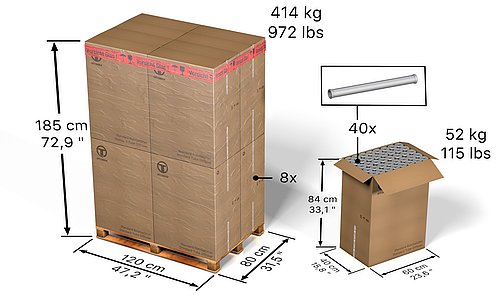

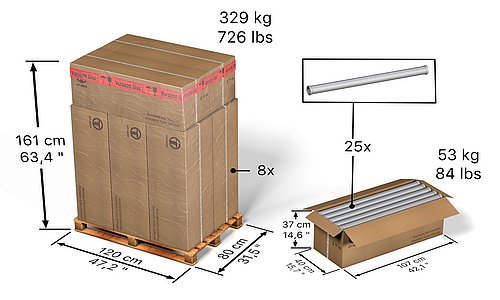

Packaging